New Additions To Our Great Metro Trucks Fleet

fadal

October 7, 2021

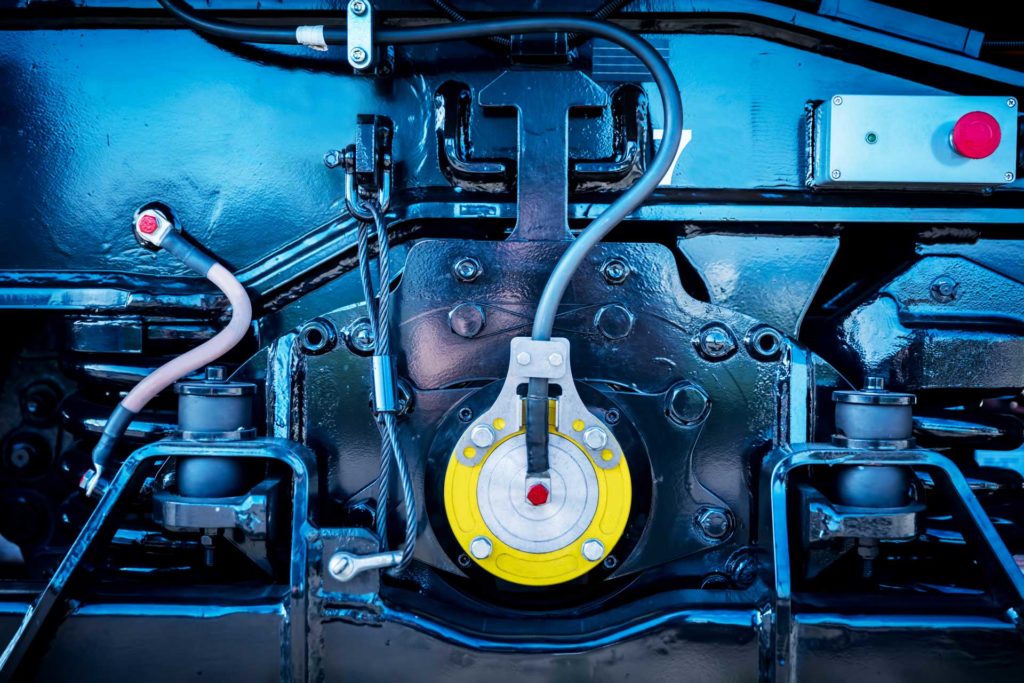

FPT Raptocut Represents a Giant Leap Forward in High-Volume, High-Speed Aluminum Plate Machining

By Ezhil Viswanathan, Vice President, Sales and FPT Machines

Aluminum is ideal for manufacturing industrial parts and tools that require anodization, high strength-to-weight ratio, conductivity, corrosion resistance, and recyclability. Add in it’s affordability and you can see why aluminum is used so frequently in manufacturing automotive, aerospace, medical, electrical and electronic, and communications products and parts.

Out With the Old

Until the invention of FPT’s RAPTOCUT, machines for aluminum were limited to vertical or horizontal milling—the subtractive process that uses rotating cutting tools to remove excess material from the workpiece.

Vertical machines produce small amounts of simple aluminum parts. But the chips—or excess material created as a byproduct from a process—don’t typically fall off in a vertical set up. This limitation results in less aluminum being removed and remachined.

Horizontal machines have different challenges. Known for creating large amounts of complex parts, horizontal milling machines have been limited to 3-axes, and the geometric parameters of cutting tools have limited the cutting force and cutting heat—making distortion of parts possible. Also, the size and payload of parts were limited.

In With The New

Enter Raptocut.

RAPTOCUT addresses the challenges of both vertical and horizontal machining by combining the advantages of both methods to help you make bigger, more complex parts more quickly and efficiently. How?

Two Pallets

RAPTOCUT does this by loading parts vertically but lifting a pallet to be machined horizontally. And it actually utilizes two pallets: one can be loaded and set up while the other is being used in machining. This feature combined with several others creates a total solution—fixturing, work holding, clamping, and tooling.

Bigger Parts

The size of parts RAPTOCUT can produce are 280” x 100” and payload to 11,000 lbs.

More Complex Geometries, More Power and Speed

This revolutionary machine offers 5-axis machining with 30,000 rpm and 130 hp spindle.

RAPTOCUT is a very unique machine with four international patents pending. It can be categorized as a “travelling-column milling machine” with lowered and symmetrical trim that—when combined with a specifically studied FMS system and tilting table—really changes the way industrial manufacturers think about aluminum plate machining.

Are You Ready?

So, who’s it for? How does your company evaluate its readiness for a RAPTOCUT?

If you have the demand for high-volume machining, the floorspace for a machine, and want to accept jobs that can handle large aluminum plates or handle multiple aluminum plates in a single setup, then RAPTOCUT is for you. And its price is competitive among other horizontal milling machines.

The Future is Here

American aerospace machining and engineering companies recognize the need to continue to enhance productivity and efficiency to remain at the forefront of global manufacturing. Investing in new and advanced technologies is critical to maintaining competitive advantage, and RAPTOCUT presents a tremendous opportunity to offer large parts and products, like bulkheads and aluminum aeronautic structural, that other manufacturers simply can’t touch.

One Comment

Leave a Reply Cancel reply

Categories

Have Any Question?

- +62 361 234 4567

- contact@domain.com

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.